Konstruujemy, wytwarzamy i uruchamiamy systemy automatyzacji wycinarek laserowych oraz automatyczne systemy składowania blach, elementów długich oraz innych materiałów o dużych masach i gabarytach. Dzięki naszym systemom możliwa jest pełna optymalizacja procesów produkcyjnych i magazynowych, poprzez odpowiednie zaplanowanie przepływu materiału oraz procesów logistyki wewnętrznej. Zapraszamy do zapoznania się z naszą ofertą.

Oferujemy optymalne rozwiązania dopasowane do potrzeb Klienta oraz pomagamy na każdym z etapów projektu. Optymalizacja procesów magazynowych poprzez zastosowanie innowacyjnej modułowości systemów oraz automatyzacji produkcji pozwala na rozbudowę w przyszłości, a możliwość integracji z innymi maszynami oraz oprogramowaniem zapewnia elastyczność.

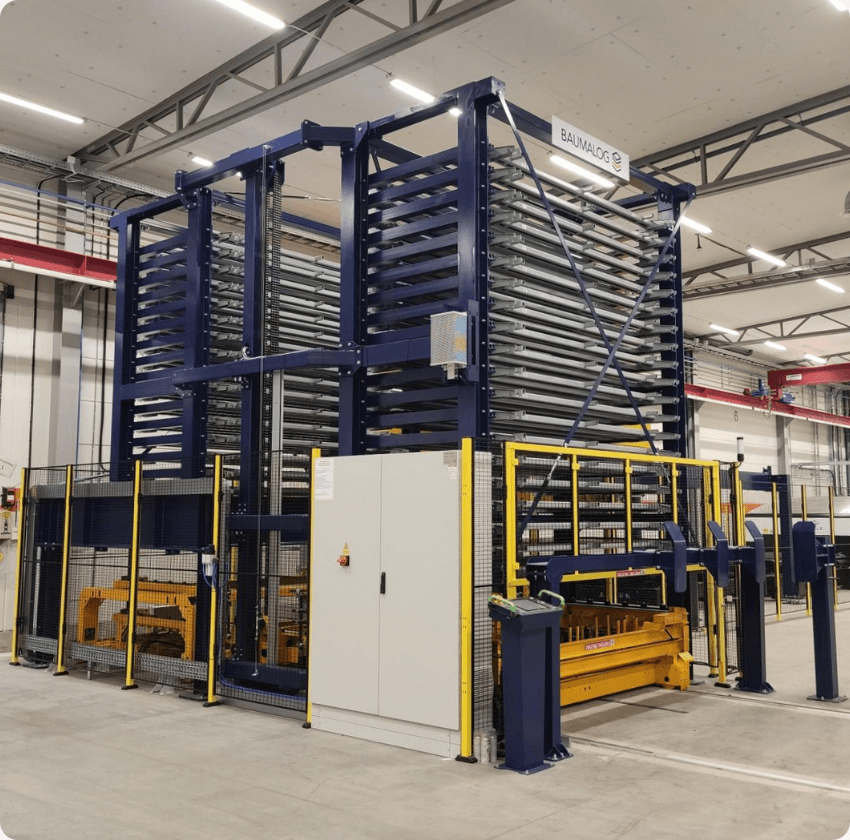

Poniżej prezentujemy wybrane realizacje systemów automatyzacji wycinarek laserowych oraz automatycznych systemów skłaodowania.

Automatyzacja składowania i przepływu arkuszy blach oraz detali wyciętych w firmie Hammar w Szwecji.

Rozbudowa magazynu automatycznego MultiTower o automatyzację przetwarzania blach dla nowej wycinarki laserowej.

Automatyzacja wycinarki laserowej marki Mitsubishi w firmie Altrad Montaż Sp. z o.o. – producenta rusztowań i szalunków.

Automatyzacja wycinarki laserowej połączona z automatycznym systemem składowania blach.

Zaplanowanie i automatyzacja procesu produkcyjnego w firmie Expo-Drew z wykorzystaniem SmartFlow System do przetwarzania blach w arkuszach.

Automatyzacja przepływu arkuszy blach w hali produkcyjnej firmy Lazam z wykorzystaniem SmartFlow System.

Optymalizacja magazynowania i przetwarzania arkuszy blach SmartFlow System z obsługę trzech wycinarek laserowych jednocześnie w firmie Termet S.A.

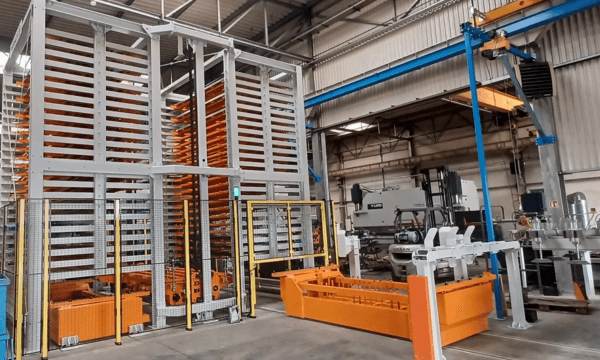

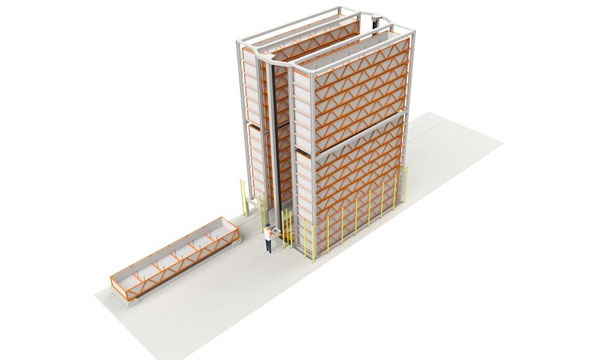

Regał automatyczny TwinTower z systemem Loader automatyzującym transport arkuszy blach do centrum obróbczego.

Wdrożenie systemu załadunkowo-rozładunkowego Loader zintegrowanego z wycinarką laserową Mitsubishi.

Dwa automatyczne systemy składowania do arkuszy blach i detali wyciętych ze wspólną bazą danych zainstalowane w firmie Galmet.

Regał automatyczny TwinTower® do składowania blach w nowej hali produkcyjnej firmy Protech kompleksowo zajmującej się obróbką stali.

Wdrożenie systemu składowania MultiTower na arkusze blach zintegrowanego z wycinarką laserową w firmie Officine Piccoli.

Automatyzacja składowania i przepływu arkuszy blach do stref maszyn obróbczych w firmie Euromilk.

Firma Metaltechnika w związku z wzrostem produkcji i optymalizacją powierzchni magazynowej postanowiła wdrożyć automatyczny system magazynowania TwinTower.

System MultiTower przeznaczony do składowania arkuszy blach zintegrowany z wycinarką laserowa.

Regał TwinTower® do składowania arkuszy blach o wymiarze 6 m x 2 m w firmie NucAir Technologies Sp. z o.o.

Regał automatyczny TwinTower® do składowania blach w firmie Hydrog, będącej jednym z największych producentów specjalistycznych maszyn drogowych w Europie.

Automatyczny magazyn blach MultiTower z układnicą magazynową dla firmy Spiroflex, specjalizującej się w obróbce metali.

Składowanie blach w regale automatycznym MonoTower® w firmie Huta Stalowa Wola.

Regał automatyczny TransferTower w firmie Atre, która produkuje meble i wyposażenie ze stali nierdzewnej dla branży HoReCa.

Wdrożenie automatycznego systemu magazynowania TwinTower na blachy i wycięte detale w firmie Vlastuin Truck.

Jednokolumnowy regał na blachy i detale wycięte MonoTower w polskiej firmie Rekord Hale Namiotowe.

Automatyczne składowanie blach na niewielkiej powierzchni w hali produkcyjnej firmy DREWMAX.

Regał automatyczny MonoTower® do składowania blach w firmie PIT-RADWAR

Rozbudowa automatycznego systemu magazynowego do składowania blach w firmie Kvader.

Wdrożenie automatycznego systemu magazynowego do składowania arkuszy blach.

Regał na blachy TwinTower® w firmie ARCOM produkującej lekkie konstrukcje metalowe m. in. systemy składowania opon dla branży motoryzacyjnej.

Wdrożenie magazynu automatycznego MonoTower do składowania arkuszy blach 6000 x 2000 mm w firmie Perfopol.

Regał automatyczny na arkusze blach w firmie Elektror Airsystems, produkującej wentylatory przemysłowe.

Francuska firma Galvasteel zdecydowała się na rozbudowę parku maszynowego o wycinarkę laserową wraz z regałem automatycznym

Regały automatyczne MonoTower® i TwinTower® do składowania blach w firmie Kostrzewa, produkującej kotły grzewcze i palniki na pelet.

Perfopol powiększył powierzchnię składowania wdrażając regał automatyczny TransferTower na arkusze blach.

Regał automatyczny do składowania arkuszy blach w firmie POM z Brodnicy, produkującej maszyny rolnicze.

Optymalizacja procesu magazynowania długich elementów i arkuszy blach za pomocą regałów MonoTower® i TwinTower® w firmie INSTAL-FILTER SA.

Regały automatyczne na profile PVC u jednego z największych producentów stolarki okiennej w Europie.

Firma Portos wdrożyła 6 systemów magazynowych TwinTower do składowania profili.

Instalacja systemu automatycznego magazynowania TwinTower w sąsiedztwie budynku, w firmie Feldmann Metall & Schmiedekunst GmbH.

Rozbudowa magazynu automatycznego na pręty stalowe w firmie Nord Napędy, która zajmuje się produkcją napędów mechanicznych i elektrycznych.

Regał TwinTower® do składowania dłużyc w litewskiej firmie Plieno Fortas, jednej z najbardziej zaawansowanych firm zajmujących się obróbką stali w krajach bałtyckich.

Firma Ponzio wdrożyła automatyczny system magazynowy na profile składający się z dwóch regałów TwinTower.

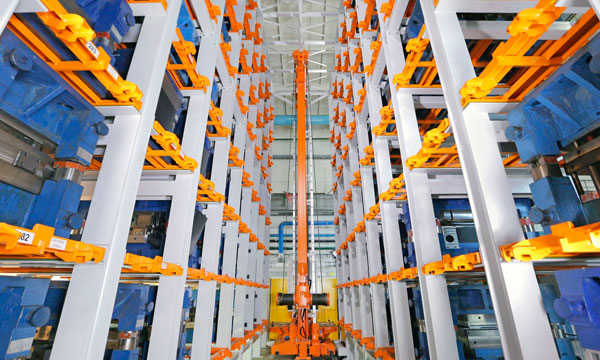

System składowania MultiTower z użyciem układnicy magazynowej w firmie Retech, specjalizujej się w obróbce stali nierdzewnej oraz produkcji oprzyrządowania elektrotechnicznego.

Składowanie profili w firmie Aluprof będącej czołowym europejskim producentem systemów aluminiowych.

Regał automatyczny TwinTower® do składowania rur w chorwackim przedsiębiorstwie Fero-Term, które jest regionalnym liderem w produkcji i sprzedaży wyposażenia łazienek.

Regał automatyczny na profile w firmie Protech, zajmującej się produkcją kotłów centralnego ogrzewania oraz świadczącą usługi przetwarzania stali.

Regał TwinTower® do składowania profili w firmie NORD Napędy w Nowej Soli.

Powiększenie automatycznego systemu magazynowania i transportu o kolejne dwa regały TwinTower.

Wdrożenie automatycznego systemu składowania TwinTower na profile w firmie Teknomet.

Składowanie profili w automatycznym regale magazynowym TwinTower® w czeskiej firmie Agados.

Składowanie matryc w automatycznym systemie składowania MultiTower z układnicą magazynową w firmie Gefest.

Automatyczny system magazynowy TwinTower na narzędzia wdrożony w firmie Mikrostyk.

Regał windowy Modula do szybkiej i bezbłędnej kompletacji w branży e-commerce.

Przechowywanie narzędzi i części produkcyjnych w regałach windowych Modula w firmie SaMASZ.

Wdrożeniu regału windowego Modula Lift do składowania części produkcyjnych w firmie Unison Sp. z o.o.

Regały windowe Modula w firmie Marma Polskie Folie, która jest jednym z największych przetwórców tworzyw sztucznych w Europie.

Wdrożenie regału windowego Modula Lift do składowania noży, głowic i części zamiennych do maszyn z branży przetwórstwa mięsnego w firmie Techjon Adam Jonasz.

Wdrożenie regału windowego Modula zintegrowanego ze stanowiskiem zrobotyzowanym w firmie Metalwit.

Wdrożenie regału automatycznego Modula w Mochnik Glass z Opola.

Składowanie elementów produkcyjnych w firmie Instal-Projekt.

Firma GKN zdecydowała się na wdrożenie dwóch regałów automatycznych Modula Slim.

Wdrożenie regałów windowych w branży automotive w firmie Polaris do składowania elementów produkcyjnych i skrzynek transportowych.

Trzy regały automatyczne Modula w magazynie serwisowym i produkcyjnym firmy Ekomex.

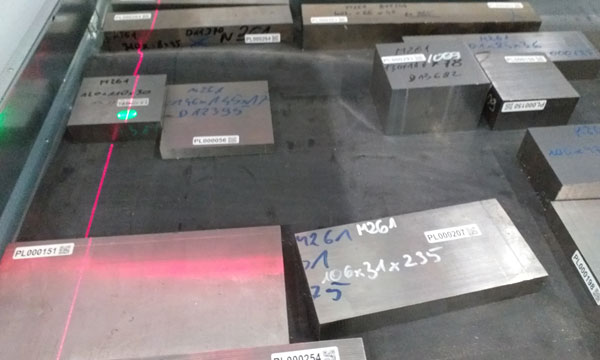

Składowanie formatek stalowych w regale windowym Modula Lift w firmie voestalpine, będącej światowym liderem w segmencie stali narzędziowych i specjalnych.

Modula Lift z oknami dostępowymi z dwóch stronach regału w firmie Spec Kable, zajmującej się dystrybucją kabli, przewodów oraz akcesoriów elektrycznych.

Wdrożenie regału automatycznego Modula Lift w firmie Tadex, wyposażonego w szereg akcesoriów umożliwiających bezbłędną kompletację.

Regały Modula Lift w firmie SSC, specjalizującej się w obróbce stali nierdzewnej oraz produkcji oprzyrządowania wykorzystywanego w branży HoReCa.

Składowanie części zamiennych do śmigłowców w regale windowym Modula w 44. “Kaszubsko-Darłowska” Bazie Lotnictwa Morskiego

Jeśli zainteresowały Cię nasze rozwiązania i zastanawiasz się jak usprawnić procesy produkcyjne i magazynowe w Twojej firmie, napisz do nas! Nasi specjaliści służą pomocą na każdym etapie – od planowania koncepcji po eksploatację.

Z dumą prezentujemy firmy i instytucje, które zaufały naszemu doświadczeniu i skorzystały z naszej oferty.